Description

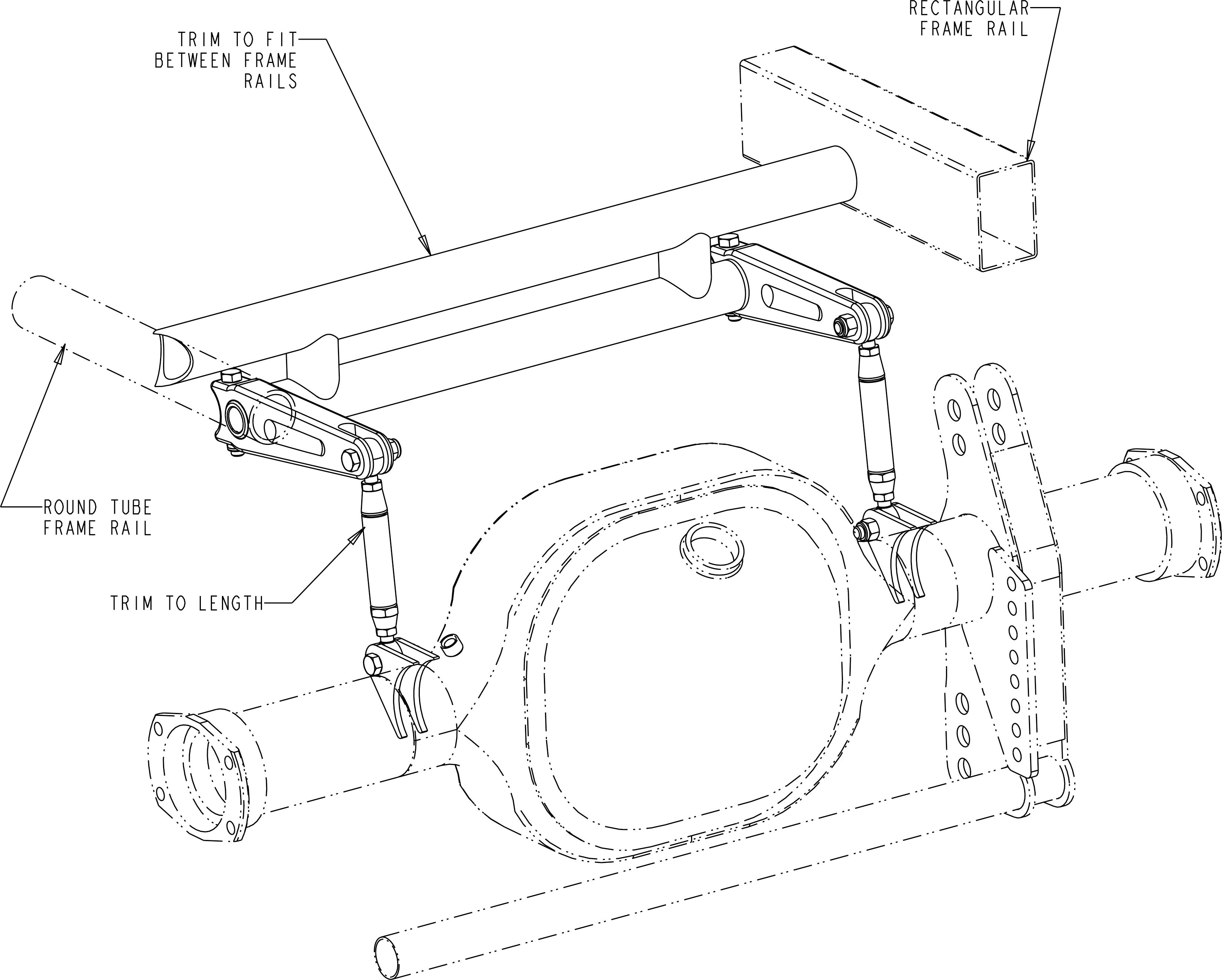

By equalizing traction preventing body roll, anti-roll or rear torsion bars, as they are sometimes called, have been shown to produce consistently quicker 60′ times.

This S&W Performance Group 21" Anti-Roll Bar Kit kit uses only the highest quality components.

- 1 1/8″ diameter x 21″ long splined 4340 steel torsional shaft (not a piece of chromoly tubing)

- Anti roll bars for S&W rear frames 10-401,10-510-26 10-511-26 as well as any other frame or, application where a 23″ long bar will fit best

- Kit has 6″ long, 1″ wide splined aluminum arms

- 1-5/8″ x .134 EWS x 36″ upper, cross-member

- 1-1/2″ x .095 DOM support tube with bronze bushings

- 3/8″ right left right ends

- 3/4″ x .058 link tubing, tabs to, mount on rear housing

Torsion Anti-Roll Bar Installation Notes

1. The drawing of the torsion bar shows the links in front of rear housing. The torsion bar will also work if it is attached to the top or the back of the rear housing.

2. Install the torsion bar with the rear housing at ride height in relation to chassis.

3. Determine the location of the crossmember so that the torsion bar and bushings can be removed for maintenance. Tack weld the anti roll bar kit in place and check clearance between arms, frame, and 4-link brackets on rear.

4. Determine length of link tubes with the suspension at ride height. There should be 4-5 threads showing on the rod ends past the jam nuts. It is typical for the rear housing to separate from the chassis during acceleration. To compensate for this when determining the length of the links, angle the torsion bar arm up approximately five degrees.

5. Before final welding the rear suspension should be moved through its full range of travel to insure that the linkage does not bind, crash or travel over center.

6. It may be easier to weld the stubs to the crossmember & torsion bar tube by removing the crossmember assembly from the car welding these components then reinstall and weld the crossmember to the frame rails.

7. It is typical for the torsion bar tube to shrink after welding. It may be necessary to hone the I.D. of the tube to install the bushings. The bushings should fit snugly. The I.D. of the bushings may have to be honed after installing them in the torsion bar tube. The torsion bar should rotates freely in the bushings when installed.

8. The initial adjustment of links should be done with car in race trim, 4-link pre-loaded and suspension at ride height. Links should be neutral with no load on the bolts.

9. Pre-loading the anti roll bar can be done by lengthening the right side link

Specifications

| For Make | |

|---|---|

| For Model | |

| For Year |

You may also like

Recently viewed

S&W Performance Group

Did you find what you are looking for? If you have any questions get in touch.